QUALITY CHECKING METHOD OF TILES

Using a master tile to match the color in every production is a common practice for maintaining consistency. By having a single master tile as a reference, you ensure that all your tile designs closely match the same color standard. This approach helps achieve uniformity and ensures that customers receive the expected color quality regardless of the design or batch of tiles they choose.

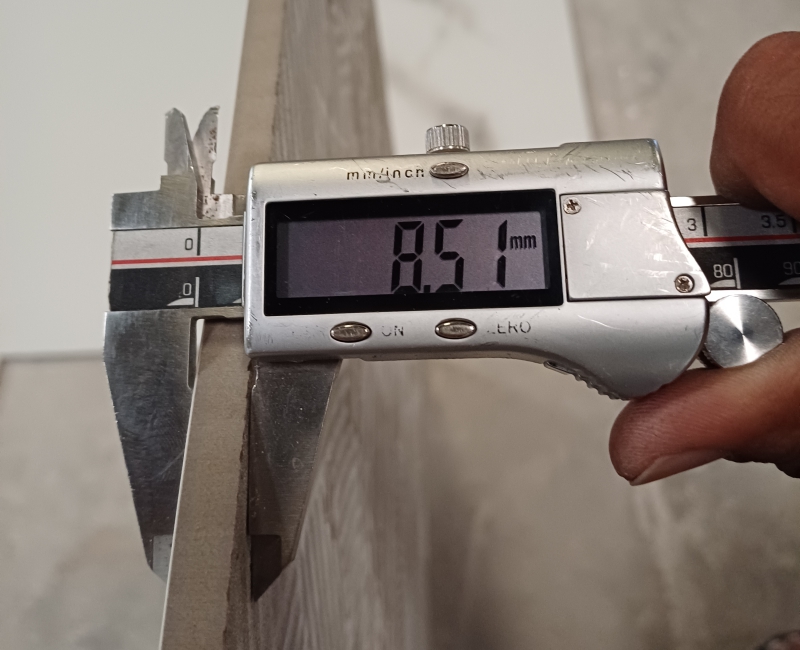

Inspecting tile thickness after production is a crucial quality control step. It ensures that the tiles meet the required thickness standards and specifications. This inspection involves measuring the thickness of each tile to identify any deviations and ensure uniformity in the final product.

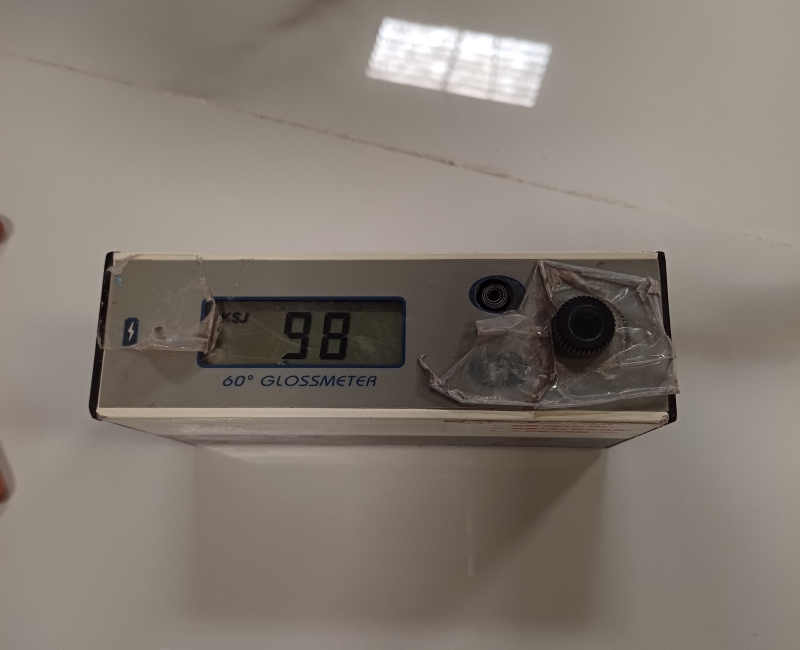

Glossiness inspection after tile production assesses the shine or reflective quality of the tile’s surface. It ensures that the tiles have the desired level of gloss, which is important for their appearance. This quality control step helps maintain consistent visual aesthetics in the finished tiles.

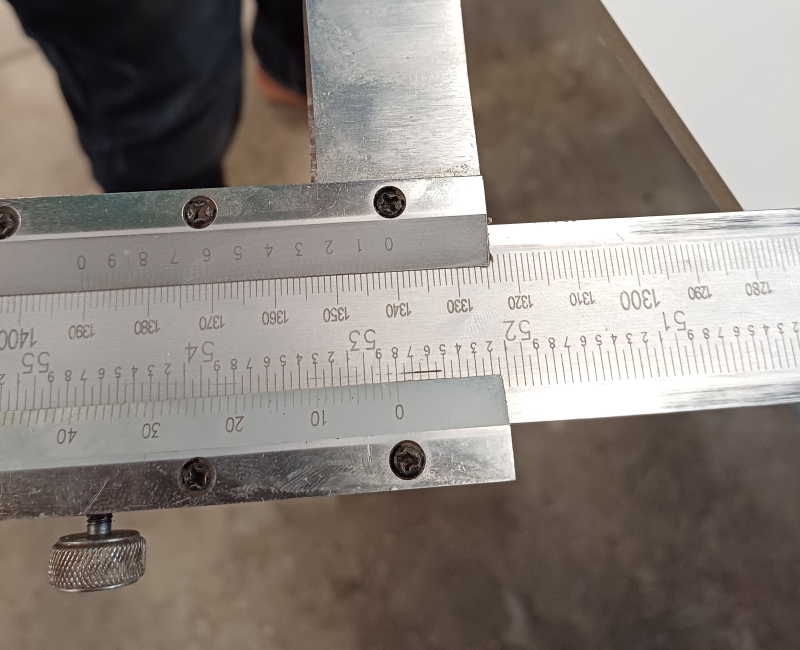

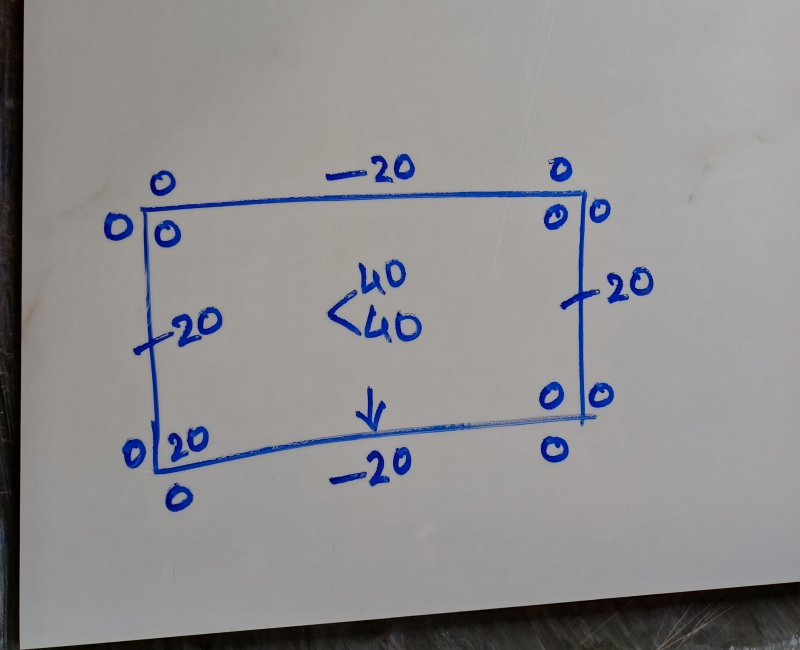

Checking tile size and diagonal measurements after production are essential for quality control. This inspection involves measuring the dimensions of each tile to verify it meets the specified size requirements. Additionally, measuring the diagonal helps ensure that square tiles have consistent angles and are not misshapen. This quality control step helps maintain uniformity and quality in the tiles produced.

Surface flatness inspection after tile production checks the evenness of the tile’s surface. It involves examining the tile’s top surface to ensure it is level and smooth without any irregularities or deviations. This inspection is important for guaranteeing that the tiles are suitable for a range of applications, including flooring, where a flat surface is essential for proper installation and aesthetics.

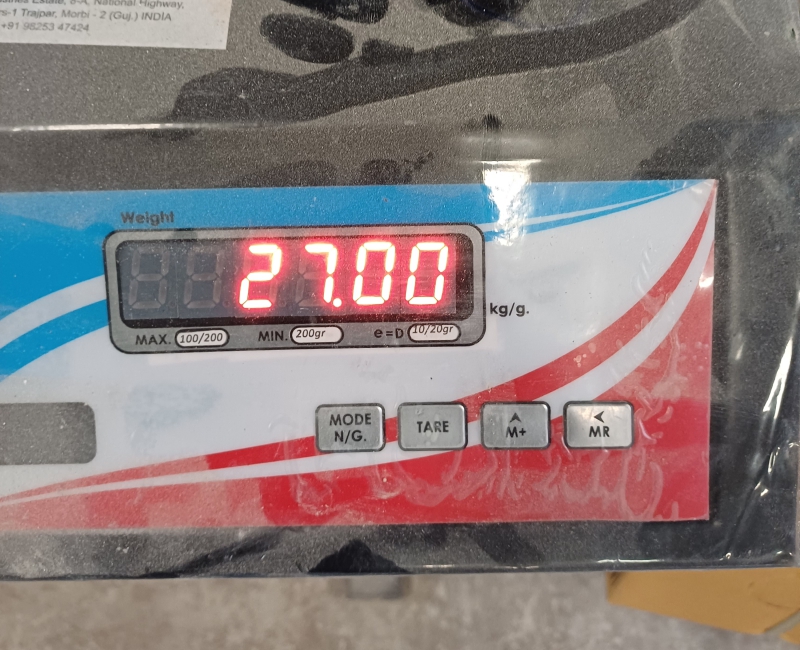

Inspecting the weight of tile boxes after production is a quality control step to confirm that the packaging meets the specified weight standards. This inspection ensures that each box contains the correct quantity of tiles and helps maintain consistency and accuracy in the product packaging process.

Water absorption inspection after tile production is a crucial quality control step. It involves measuring the tile’s ability to absorb water, which is essential for determining its suitability for different applications. Tiles with low water absorption rates are typically preferred for areas like bathrooms or kitchens where moisture resistance is important. This inspection ensures that the tiles meet the required standards for their intended use.

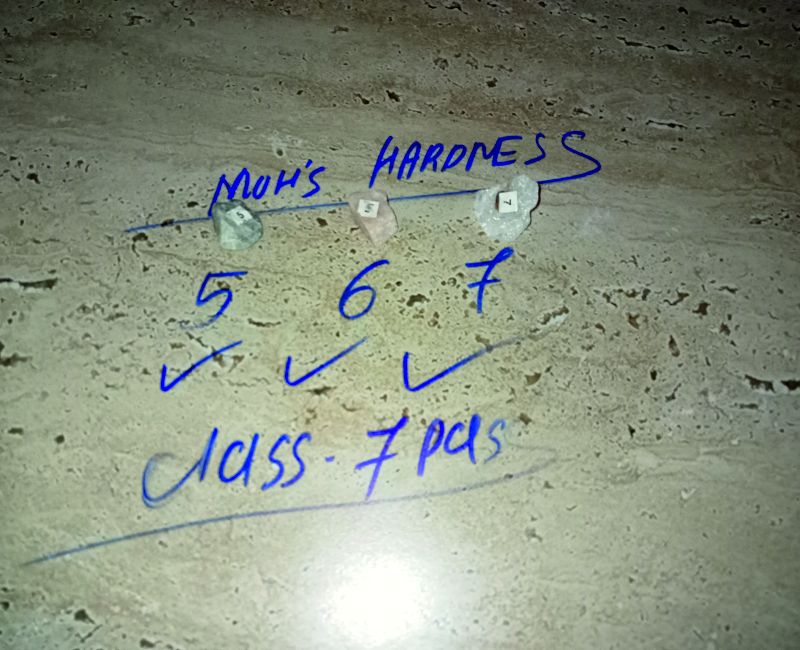

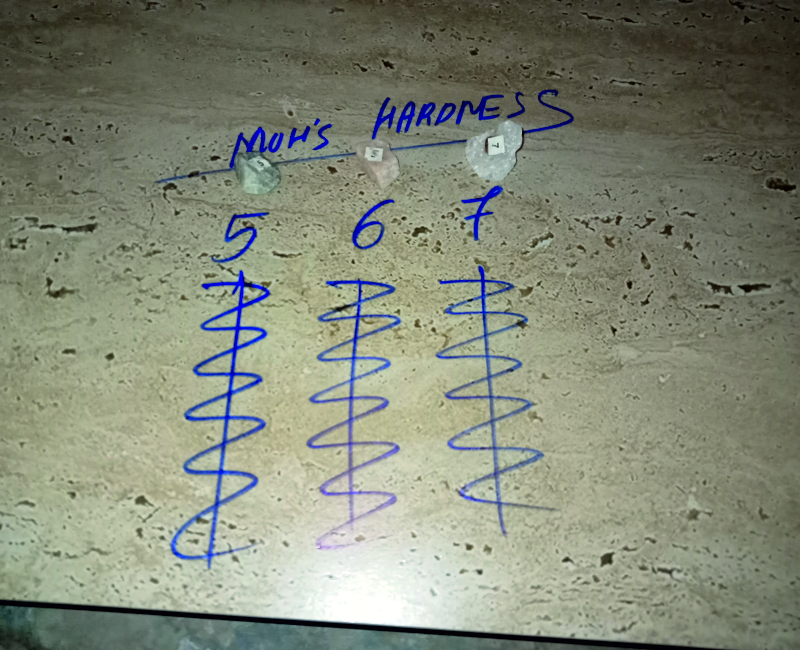

The roughness of a surface refers to how smooth or uneven it is. In the context of tiles, it relates to the texture or feel of the tile’s surface. Some tiles are very smooth, while others have a more textured or rough surface. The level of roughness can affect the tile’s appearance, ease of cleaning, and suitability for different environments.

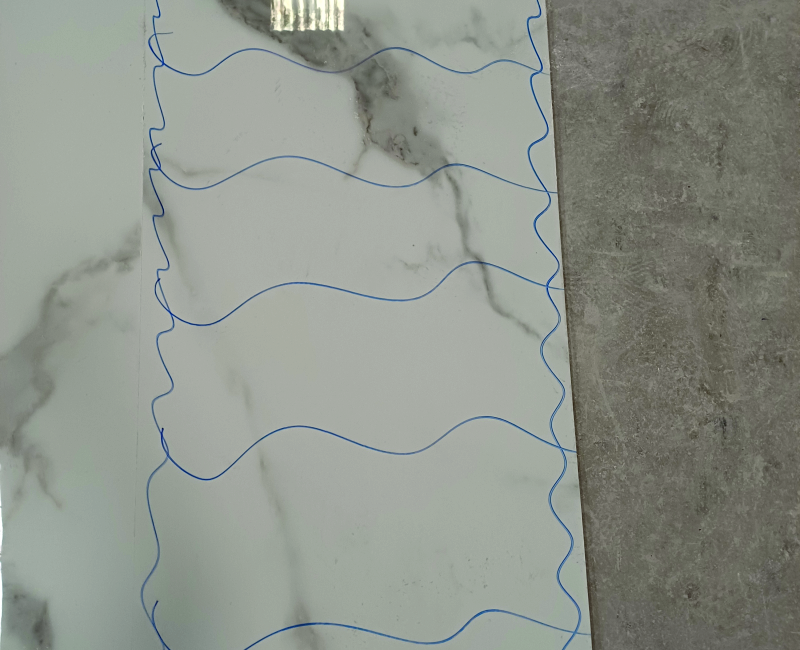

Indeed, checking the curvature of tiles by placing two tiles together is a practical method. When two tiles are placed side by side, any noticeable gap or misalignment can indicate curvature issues. If the tiles fit together seamlessly without gaps, it suggests that their curvature is acceptable, and they are well-suited for installation. This simple visual inspection helps ensure that the tiles will create a flat and even surface when laid out, which is important for both aesthetics and functionality

MOR (Modulus of Rupture) inspection after tile production assesses the tiles’ strength and durability. It involves subjecting samples to a bending or breaking test to measure their resistance to force. This test helps ensure that the tiles can withstand typical stresses and loads they might encounter during use, ensuring their quality and longevity.

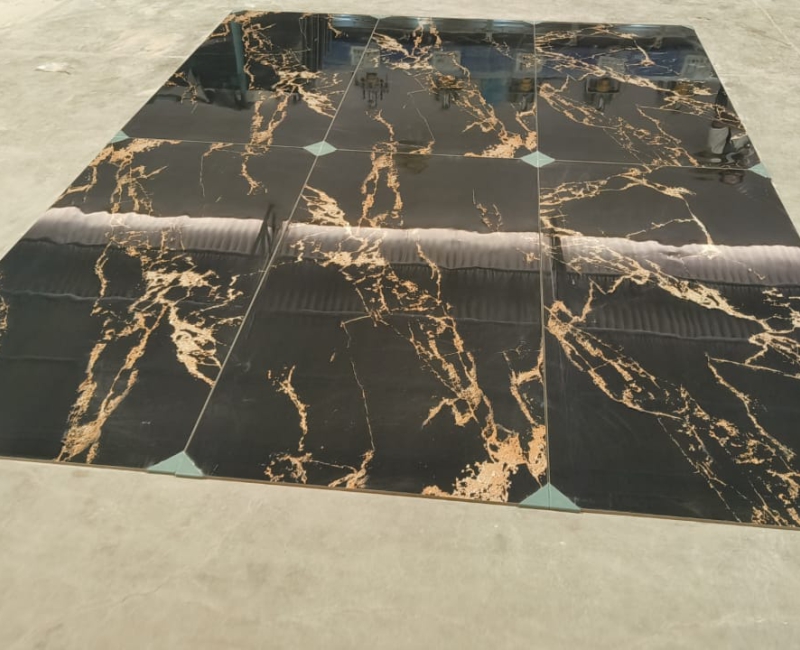

Opening random boxes of tiles and doing a flooring test is an effective way to visually inspect and confirm color and design consistency. This method allows you to see how the tiles will look when installed, ensuring that the design and color variations meet your expectations and maintain a consistent appearance across the entire surface. It’s a practical quality control step to ensure that the final result in any space is visually pleasing and uniform.

Easy to clean” inspection after tile production involves evaluating the tiles to ensure that their surfaces are designed for easy cleaning. This inspection checks if the tiles resist staining and dirt buildup, making them simple to maintain. Tiles that pass this inspection are more convenient for homeowners or businesses to keep clean and looking good.

SERVICE PROCESS OF IRAZO

Confirm Order With Buyer

Taking Sample List From Buyer

Confirm Randoms of Design With Buyer

Design Matching

Checking Running Production

Ordered Production Start

Checking Live Production

Checking quality of Finished Product

Sending QC Report And Videos To Buyer

Tacking Quality Confirmation With Buyer

Pallet Packing

Loading And Send Loading Photo To Buyer

Taking Document Confirmation With Buyer

Sending Live Tracking To Buyer Every Week.

Getting Feedback From Buyer About Materials And Sample

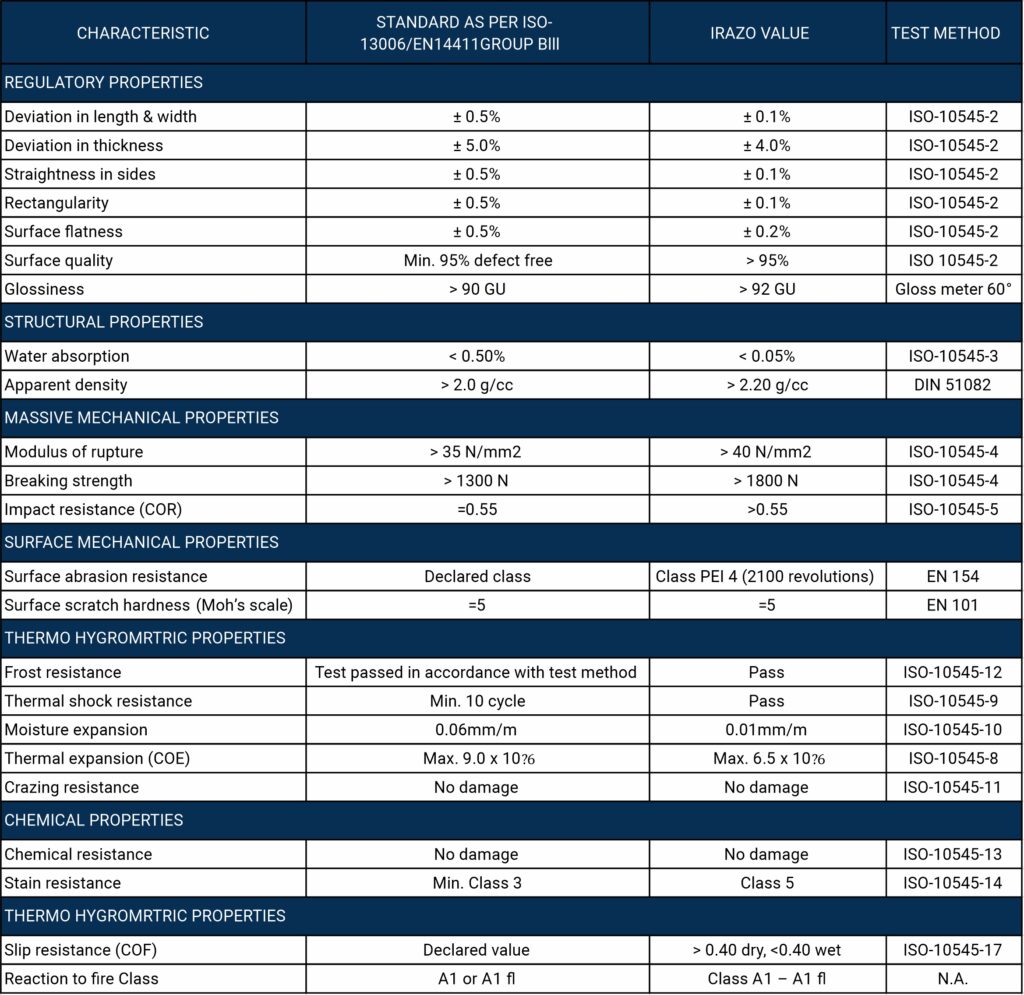

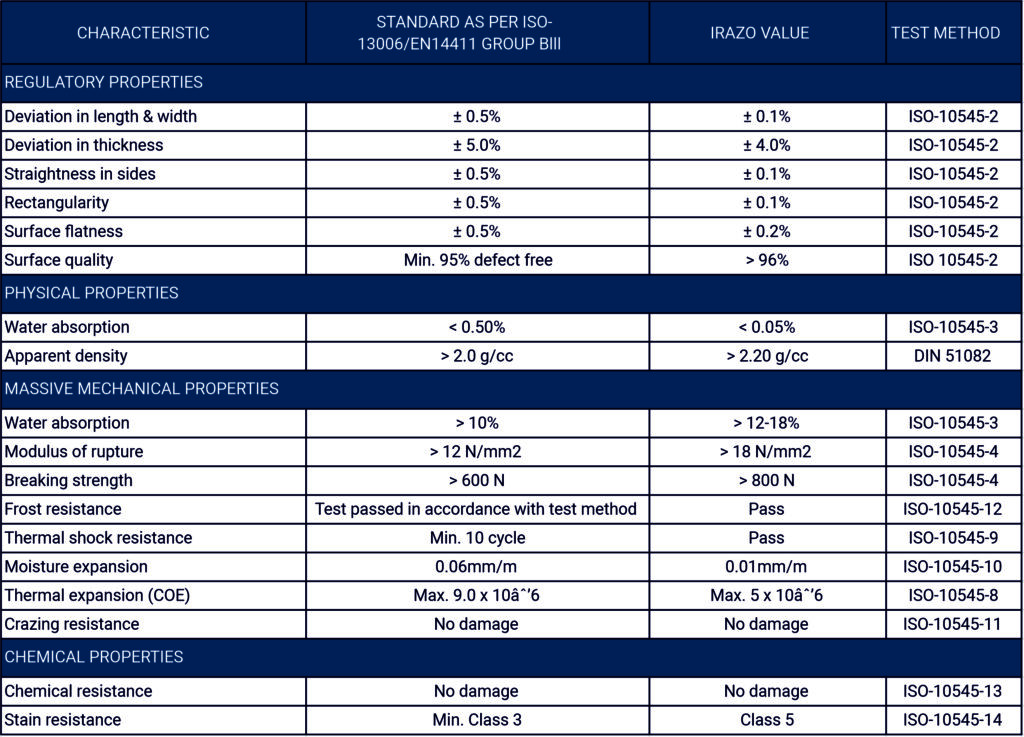

IRAZO CERAMIC TECHNICAL SPECIFICATION

KEY TYPE INSPECTION OF IRAZO

Pre-production inspection of tiles involves evaluating the initial materials and processes before the actual tile production begins. This inspection is crucial to ensure that the raw materials, equipment, and production methods meet the required standards and specifications. It helps identify and address potential issues early on, preventing quality problems during the manufacturing process and ensuring that the final tiles meet the desired quality and consistency.

In-process inspection of tiles occurs during the actual tile manufacturing process. It involves regularly checking and monitoring various production stages to ensure that quality standards are maintained. This inspection may include assessing factors like color accuracy, size, thickness, surface finish, and other quality criteria as the tiles are being produced. The goal is to catch any deviations or issues in real-time, allowing for adjustments and corrections to ensure the final product meets the desired quality standards.

Final inspection of tiles is the last quality control step before the tiles are ready for distribution or use. During this stage, a comprehensive assessment is conducted on the finished tiles to verify that they meet all the specified quality criteria and standards. This includes checking for consistency in color, size, thickness, surface finish, and any other attributes. Tiles that pass the final inspection are deemed suitable for sale or installation, ensuring that customers receive high-quality products.